ITE-SP-8660

ITE-SP Multiple axes spring compression CNC Machine:

- Versatility:

Capable of producing compression springs with wire diameters ranging from 0.15mm to 12.0mm.

- Modern Technology:

Equipped with a high-speed and high-precision computer-controlled servo system.

- User-Friendly Interface:

Features a computer screen displaying axis positions, wire feed information, production speed, and quantity, with

easy program setting and adjustment via keyboard.

- Flexible Adjustment:

Convenient pitch adjustment and independent outer diameter axis for easy customization.

- Enhanced Production Capability:

Produces various compression spring shapes without mechanical adjustments, eliminating the need for cam

piece replacement.

- Wide Range of Applications:

Suitable for all types of compression springs, including oil seal springs, pagoda springs, clockwork springs, and

complex and special-shaped springs.

Experience superior precision and efficiency in compression spring manufacturing with our advanced CNC spring compression machine.

Automatic material feeder frame Automatic material feed frame ITE-150-350-500-1000

(weight bearing between 150-1000 Kg)

Characteristics: timing, disconnection, (starved feeding), abnormal stops (deviation), automatic alarmstop run, induction control. high safety control compatibility, can use for parallel or serial electric production machinery, to independent or synchronization feeding material.

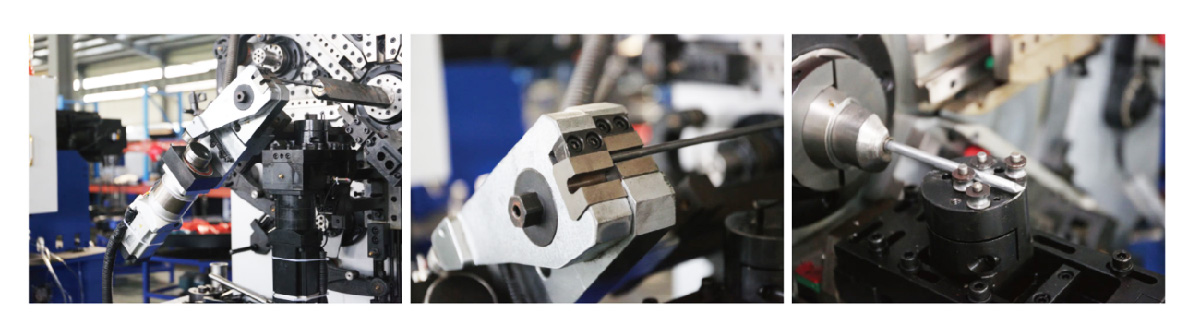

Spinner axis/ Servo motor cutter axis

Our brand portfolio epitomizes excellence and innovation, offering a spectrum of premium choices tailored to discerning customers worldwide. Explore our range where quality meets ingenuity, promising unparalleled satisfaction and inspiration.

Our brand specializes in a range of precision CNC machinery tailored for diverse industrial applications. From flat forming to copper plate bending, and from multiple axes spring compression to cam spring CNC machines, our products epitomize cutting-edge engineering and innovation. With a commitment to quality and performance, our brand stands at the forefront of providing advanced solutions to meet the evolving needs of industries worldwide.

Our brand specializes in a comprehensive range of advanced manufacturing solutions, including fiber laser cutting machines, welding machines, marking machines, and CO2 engraving machines. Additionally, our product lineup encompasses flexible bending centers, bending machines, and roll forming machines. With a commitment to innovation and precision engineering, we deliver cutting-edge technologies to empower industries worldwide, driving efficiency, productivity, and excellence in manufacturing processes.

Our brand is a leader in providing cutting-edge solutions for pipe welding production lines. With a focus on precision engineering and innovative technology, we specialize in delivering comprehensive solutions tailored to the specific needs of pipe welding processes. From automated welding systems to seamless integration and optimization, our products ensure efficiency, quality, and reliability throughout the production line, empowering industries to meet their manufacturing challenges with confidence and excellence.